We sat down with Pete, R&D Engineer at Stashed, to dig into the process behind our UK-made bike storage systems. From first sketch to final test, Pete shares how our team designs, engineers and perfects modular bike racks that make your ride smoother and your space better.

Whether you're looking for garage bike organisation or premium storage that feels good to use, here's how we bring it to life.

What materials are Stashed products made from?

We use high-performance materials that are chosen for strength, precision and durability.

-

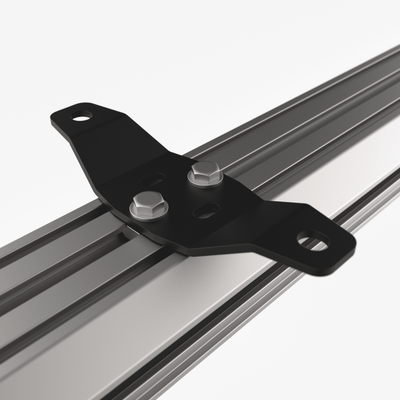

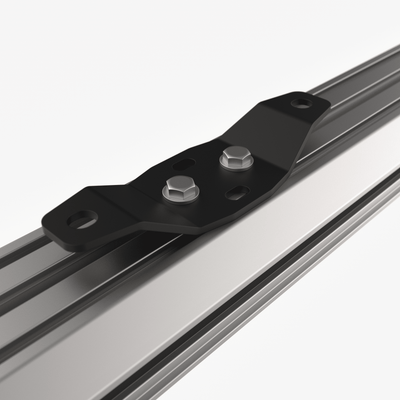

Extruded 6063 aluminium for the rails

-

Laser-cut S275 mild steel with powder-coated finish

-

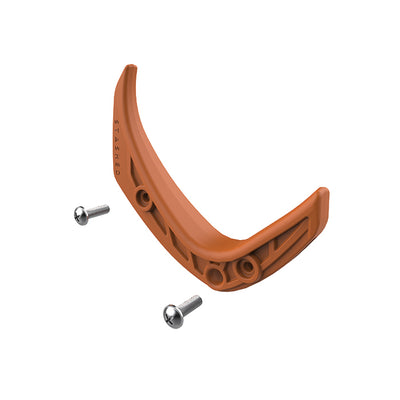

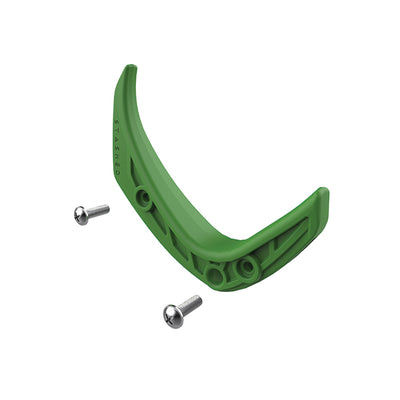

Injection-moulded technical plastics including glass-filled nylon and acetal

These materials are built to handle heavy bikes, long-term use and everyday movement. They give our space-saving bike racks a premium feel that lasts.

Where are Stashed systems made?

All Stashed bike storage products are manufactured in the UK. Our components are sourced from trusted suppliers across Wales and the wider UK, and final assembly is done in-house at our Mid-Wales facility. This allows us to control every stage of production and maintain consistent quality.

What makes Stashed storage different?

Our customers often tell us that what stands out is the engineering precision and attention to detail. Every element is designed to move smoothly, hold securely and feel solid. We don’t release anything until it works beautifully.

From the click of a hook to the glide of a rail, everything is built for riders who care about gear, design and experience.

How do new products get developed?

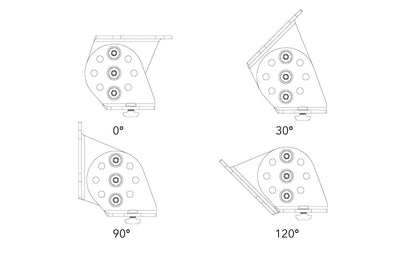

Every new product starts with a problem. We explore the issue, sketch ideas, 3D model the parts and prototype using both printed plastics and real materials. Then we test, revise and test again, sometimes hundreds of times.

Nothing is rushed. Each design is refined until it fits into our goal of making life stored better.

Can I suggest an idea?

Yes. We love hearing from our community. Whether it’s a feature you’d love to see or a challenge in your storage setup, just send us a message. Some of our best innovations have started with real rider input.

How do you test your bike storage systems?

We test throughout the entire development cycle. From digital stress tests to physical break tests, our products are pushed well beyond everyday use. This ensures they hold up to the demands of real riders using e-bikes, mountain bikes and road bikes alike.

What makes a product feel right?

There’s always a moment where a design clicks. Sometimes it comes quickly. Other times it’s the result of dozens of tiny refinements. A great product disappears into your routine. It just works. That’s our benchmark.

Where does your design inspiration come from?

We draw ideas from cycling gear, industrial design, motorsport, architecture and even sci-fi. Form always follows function, but that doesn’t mean we ignore style. Once the engineering is right, we refine the look so it feels clean, modern and at home in your space.

What was the biggest challenge in designing the SpaceRail?

Designing the aluminium extrusion for SpaceRail was a major moment. You can test the shape in 3D prints, but at some point, you have to commit to full production. That first batch arriving and fitting perfectly was a huge milestone.

Are there small details you’re proud of?

Definitely. There’s a stepped plate in the Freestand frame that helps locate the rail perfectly. It’s small and mostly hidden, but it makes installation smoother and the whole system more secure. It was one of my first contributions to Stashed and it still makes me proud.

What’s coming next?

We’ve got some exciting new designs in the pipeline that we believe could become essentials in modern bike spaces. We can’t say too much yet, but we’re pushing into new territory with modular bike organisation that goes beyond what’s currently available.

What happens after launch?

We keep listening and improving. Watching how people use our products often leads to new accessories or unexpected design tweaks. We build everything to last, but we’re always learning and evolving.

What brands do you admire?

I’ve always been drawn to brands that mix function with personality. In cycling especially, the ones that innovate confidently, look great and solve real problems stand out. That’s what we aim for too.

Final thoughts?

At the end of the day, we build storage that lets riders focus on the ride. If we’ve done our job right, your space is tidier, your prep is smoother and you’re out the door faster.

Ready to upgrade your storage?

Browse our full range of bike storage systems and accessories designed for riders who want better performance from their setup.

Every product is made in the UK. Engineered for life on two wheels.