Behind the Scenes: How We Test Every Stashed Product to Perfection

At Stashed, every product that leaves our workshop has been through a meticulous testing process to ensure it meets our standards for quality, strength and reliability. We design for riders who demand the best, and that means our products are built to handle far more than everyday use. Here’s how our R&D team puts each piece of gear to the ultimate test.

1. Starting with Precision

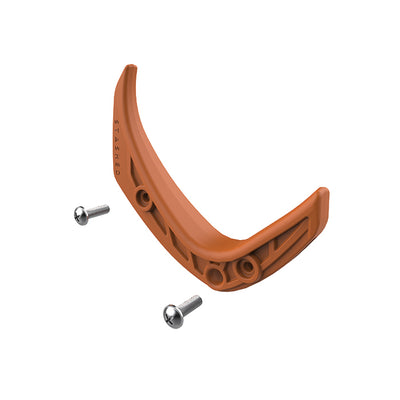

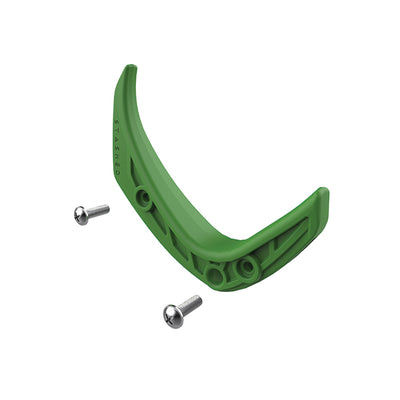

Before a part even makes it to a prototype, it’s checked against our detailed engineering drawings. Our operations team inspects every measurement and surface finish, searching for even the smallest imperfection. Only components that meet our exacting standards move forward.

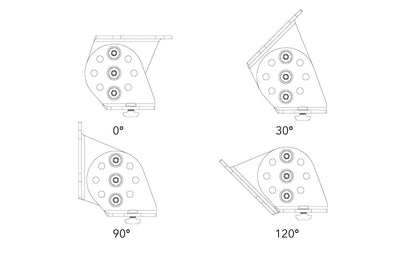

2. Simulating Real Life and Beyond

We don’t just think about how our customers will use our products – we actively recreate those conditions in our workshop. Prototypes are tested with real bikes and gear, then pushed beyond normal use with heavy weights and precision strain gauges to uncover their absolute limits.

3. Extreme Durability Testing

From repeated loading and unloading cycles to staggering weight trials, our tests go well beyond industry norms. If a hook is designed to be used 10,000 times, we make sure it’s tested exactly that many cycles. For load-bearing systems, such as those carrying up to eight full-sized e-bikes, we test not just the rated weight of 240kg – but as much as 500kg.

4. Safety and Reliability Under Pressure

We deliberately overload components far past their intended limits to understand exactly when and how they will fail. This gives us complete confidence that every product you buy is more than strong enough for the job.

5. Continuous Improvement Through Testing

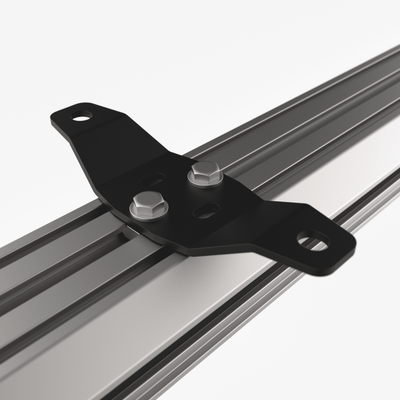

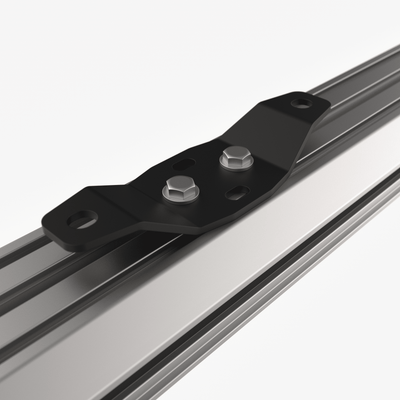

Testing isn’t just about confirming a design, it’s about refining it. For example, during late-stage trials of our Freestand frame, we discovered that under misuse the frame experienced slight lateral movement. We redesigned the system, adding extra bracing for even greater stability.

6. Balancing Strength and Weight

6. Balancing Strength and Weight

While our products are rarely carried or moved, weight becomes a factor in some designs – such as the Freestand frame, for ease of assembly, mobility and shipping. Early prototypes used lightweight aluminium, but we chose steel for the final version, delivering superior strength without compromising usability.

7. Measuring Performance with Precision Tools

We rely on specialist load-testing machines (we’ll leave the exact names to our engineers) alongside precision tools like verniers and callipers to measure dimensional changes over time. Visual inspections check for wear, ensuring that every component meets our expectations for longevity.

8. Knowing When It’s Ready

A Stashed product is ready for launch only when we can no longer improve it, when every compromise has been weighed, and every test passed with confidence. That’s when we know it’s ready to take pride of place in your space.

At Stashed, testing isn’t just a stage in our process,it’s part of our DNA. It’s why our products last, perform and look great doing it. Because if it doesn’t pass in our workshop, it will never reach yours.